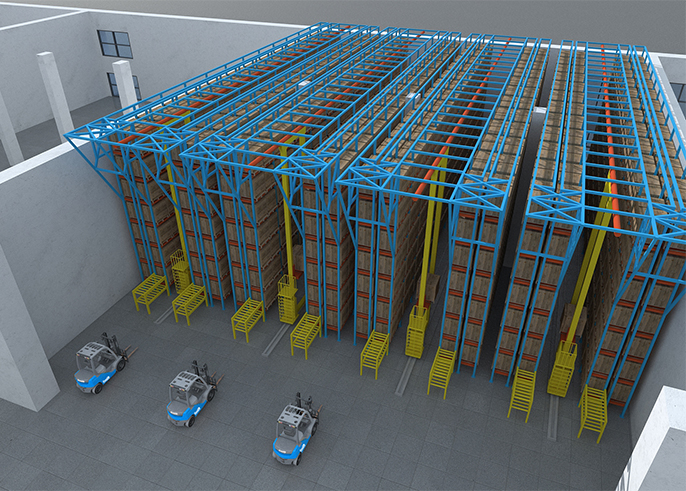

Automated warehouse system (AS/RS) consists of three-dimensional shelf, rail roadway stacker, pallet conveyor system, size detection for ins and outs of barcode reading system, communication system, automatic control system, computer monitoring and control system, computer management systems, and other such AS wire and cable tray distribution cabinets, tray, adjust the platform and other auxiliary equipment, steel structure platform composed of complex automation system. Using the first-class integrated logistics concept, using advanced control, bus, communication and information technology, through the coordinated action of the above equipment warehouse operation. In terms of management, computer and bar code technology are adopted. The pallet is used as the storage unit. The stacker is mainly used to shuttle back and forth between the laneways of the three-dimensional warehouse, and the goods located at the laneway are stored in the cargo compartment, or the goods in the cargo compartment are taken out and transported to the laneway.

Features:can achieve dense storage, make full use of space, the height is usually designed in 7-30 meters, at the same time to achieve high-speed storage capacity, the ability of a single stacker can reach 45-50 pallet/hour, is a widely used storage mode.

Suitable for:dense storage, bulk, fast in and out items, also suitable for -25 degrees cold storage projects.

High safety

The stacker is designed according to the highest safety level in Europe

High hardware configuration

Key components and controllers are European high-end brands

High control performance and rich functions

1. Operate the stacker with multiple positions and time sharing

2. Applicable to storage requirements of complex cargo boxes

3. High-speed and smooth operation curve

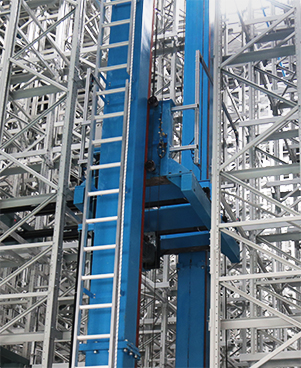

Hoist the wire rope

6 times safety factor design, the choice of imported lubrication free wire rope

Catcher

Abnormal and overspeed lifting can effectively put the pallet tongs on the guide rail of the upright column

Cases and Application

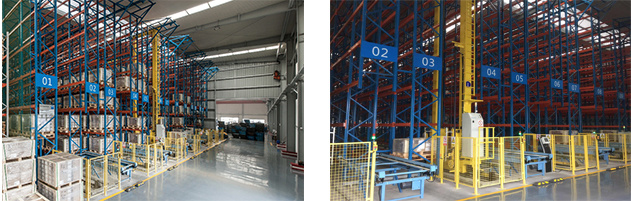

Hardware Company

The hardware company has been engaged in the production and sales of fastener products. With the steady development of the company’s business, the production and sales scale of fastener products has further increased. The existing production base cannot meet the growing production scale and requirements. Therefore, the company has constructed a new factory area and moved to the new production base in 2016 to expand production. In the old production base, the company works with the traditional warehouse storage mode and found that the traditional warehouse storage has a series of problems, such as low work efficiency and high human cost, which has brought some problems to the enterprise operation. In order to ensure the good operation of the company’s business, the automated stereoscopic warehouse designed and established by Eoslift was introduced in 2016. The project covers an area of about 2,000 square meters with a total shelf height of 10 meters. It consists of 14 rows of shelves in 7 lanes. Each shelf has 7 stories, totaling 4,200 shelves. Two stackers are used alternately in 7 lanes under the mode of transition. In terms of storage mode, the automated stereoscopic warehouse adopts lane stacker, which can meet the requirements of first-in-first-out of goods and large flow of goods entry and exit in warehouses. In terms of cost reduction, there are so many staff in traditional warehouse that the operating environment is poor with high error rate, which brings direct and indirect cost increases to enterprises. Automated stereoscopic warehouse realizes the automation and intellectualization of storage, reduces the number of staff, and reduces the labor intensity accordingly, so as to save the cost of enterprises. In terms of technology optimization, WMS warehouse management system based on RFID technology in automated warehouse can realize the real-time entry and exit of good, inventory control and delivery on the basis of traditional warehouse management system combined with the most advanced RFID (electronic tag).