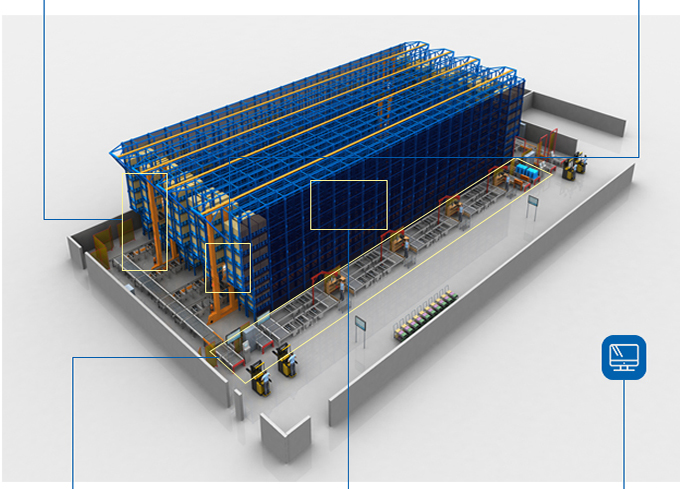

This stacker is a kind of automatic material handling equipment and is the core component of our stereoscopic warehouses. Stereoscopic warehouses can improve the utilization ratio of large unit areas, increase labor productivity, reduce labor intensity and production cost, reduce errors in goods and information processing, reasonably and effectively carry out inventory management control of materials, better meet the needs of special warehousing environment, improve operation quality, ensure the safety of goods in the whole warehousing process, and make it easy for system integrations of other technology.

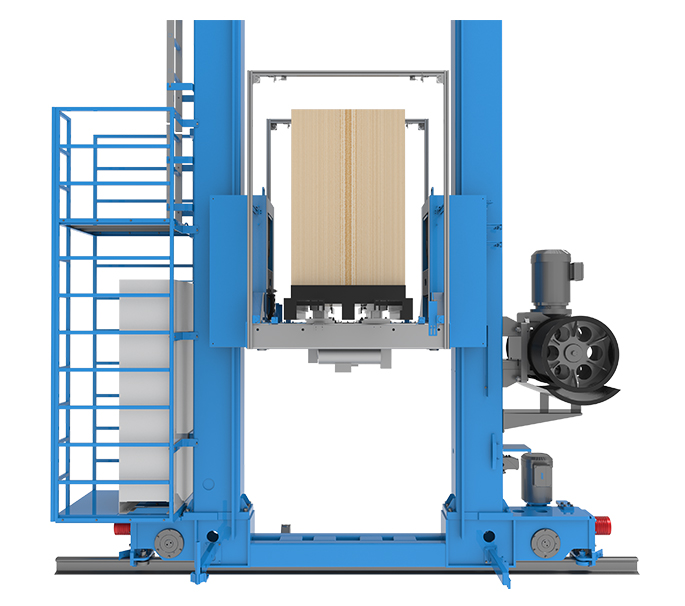

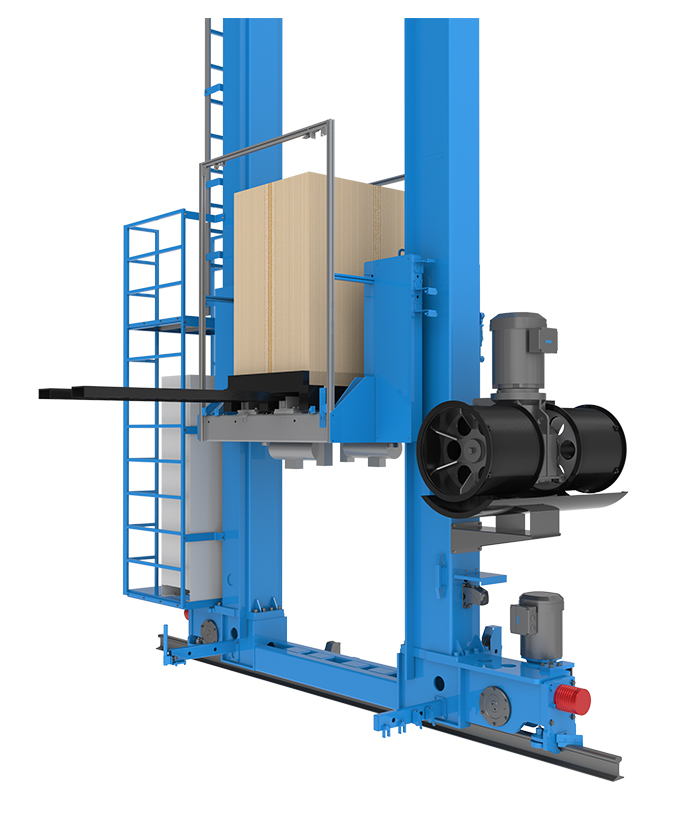

Eoslift stacker is designed to improve system operation capability. Horizontal walking speed, lifting speed, fork speed, acceleration and deceleration speed, and precise positioning have been taken into consideration by Eoslift to provide an ideal integrated solution. Machine selection can meet all kinds of unique needs, which has provided a good method for improving warehouse performance and balancing costs.

Sky/Ground Rail

The Eoslift stacker adopts sky rail and ground rail systems, and all the rails in the system are produced by Eoslift certified suppliers in same batch. The quality of the supplier’s products enjoys excellent reputation in the industry, ensuring that the system has sustained high performance measurers.

Pallet stacker

Pallet stackers are much more efficient than forklift vehicles. Efficient stackers can meet your access needs in roadways. Eoslift stacker can be widely used for different unit loading range and warehouse height.

In-out Warehouse Station

All series of pallet conveyors and AGV produced by Eoslift are committed to meeting the needs of different customers. Therefore, there many options of in-out warehouse stations for selection from the cost-effective fixed workstation to the full-automatic solution, which can seamlessly connect the production area, the conveying area, the sorting area, the storage area and the receiving area. Our goal is to improve the working efficiency of customers and save their time.

Goods Shelves

Eoslift shelves are subject to high-demand quality inspection and certification to ensure that the shelf system meets national standards. Eoslift is fully responsible for seamless integration of shelves and equipment to ensure uninterrupted and efficient work.

Control and Software System

Eoslift stacker adopts control and software system independently developed by themselves. Intelligent location control software is connected with warehouse management system or enterprise resource planning system (ERP) to ensure the safety, control, and management of production. Users can view the order status and the provided service diagnostic information on the system.

| Rich Industry Experience | |

| Efficient and Professional After-sales Service | |

| Excellent Product Performance | |

| Special Design According to Customer’s Special Working Environment | |

| Compliance with Europe’s Highest Security Level | |

| Low Energy Consumption and Energy Recycling Technology |

| Conventional Stacker ES | |

|---|---|

| Maximum Load Capacity | 1102.3-3306.9 lb |

| Maximum Height | 275.6-984.3 in |

| Travel Speed | 7086.6 in/min |

| Travel Acceleration | 13.8 in/s2 |

| Hoisting Speed | 2362.2 in/min |

| Hoisting Acceleration | 19.7 in/s2 |

| Fork Speed | 31181.1/2362.2 in/min |

|

|

| Light Stacker EM | |

|---|---|

| Maximum Load Capacity | 44.1-440.9 lb |

| Maximum Height | 118.1-315 in |

| Travel Speed | 8661.4 in/min |

| Travel Acceleration | 31.5 in/s2 |

| Hoisting Speed | 2362.2 in/min |

| Hoisting Acceleration | 019.7 in/s2 |

| Fork Speed | 31181.1/2362.2 in/min |

|

|

| Overweight/Ultra High Stacker EH | |

|---|---|

| Maximum Load Capacity | 44.1-440.9 lb |

| Maximum Height | 118.1-315 in |

| Travel Speed | 8661.4 in/min |

| Travel Acceleration | 31.5 in/s2 |

| Hoisting Speed | 2362.2 in/min |

| Hoisting Acceleration | 019.7 in/s2 |

| Fork Speed | 31181.1/2362.2 in/min |

|

|

| Transfer StackerEP | |

|---|---|

| Maximum Load Capacity | 1102.3-17637 lb |

| Maximum Height | 275.56-984.3 in |

| Travel Speed | 4724.4 in/min |

| Travel Acceleration | 13.8 in/s2 |

| Hoisting Speed | 1181.1 in/min |

| Hoisting Acceleration | 19.7 in/s2 |

| Fork Speed | 1181.1/2362.2 in/min |

|

|